Dream It

Everyone has an idea for a cool project, but not everyone has the knowledge and tools to get it done. If you can think it up, you can bring it to life here.

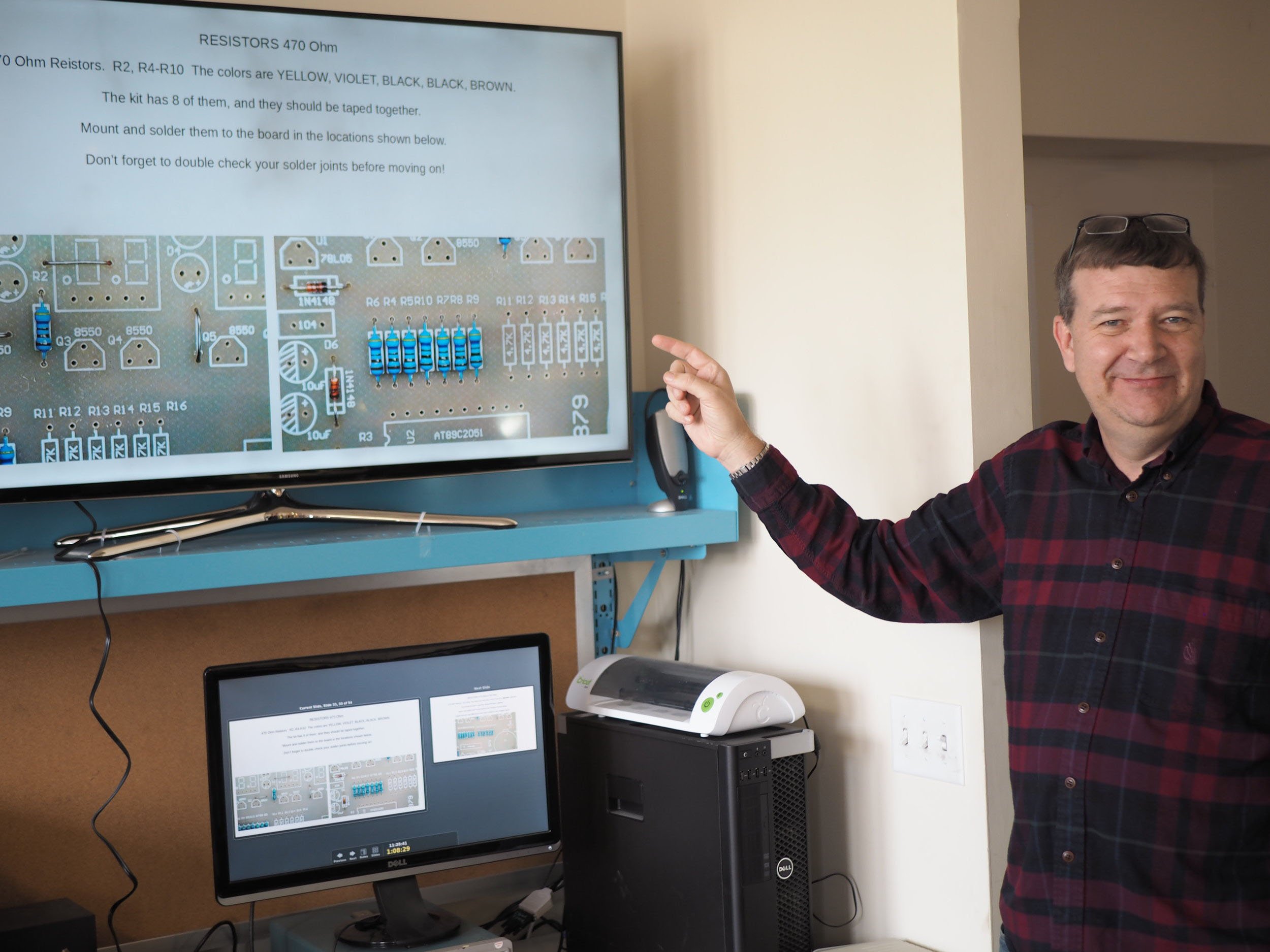

Learn It

We offer training classes and workshops covering a wide variety of subjects. Whether it's Arduino programming, laser cutting, 3D printing, CNC machining, or welding, our members have a wealth of knowledge to share with anyone willing to learn.

Make It

Ultimately, the purpose of a makerspace is to remove barriers so you can create awesome things! With our diverse membership skill set and access to our large selection of tools, you can turn your dreams into reality.